Thermal Conductivity Tester fabrication|thermal conductivity testing methods : sourcing At Thermtest, we can provide thermal conductivity testing services from low to high conductivity materials including solids, liquids, pastes, powders, soils, . La Quiniela Plus nro. 12084 de fecha 21/02/2024 ha quedad.

{plog:ftitle_list}

WEBAnálise. A 8/10 2023, a Guaireña jogou com a Libertad na Division Profesional. 74/5000 A partida terminou 1 - 5 para Libertad . Uma vez que o jogo já terminou, sugerimos-te que .

TA Instruments steady-state heat flow meters allow for the direct measurement of thermal conductivity of materials that span from insulation building materials to polymers, composites, ceramics and refractories according to a large number of ASTM, ISO and EN standard methods.At Thermtest, we can provide thermal conductivity testing services from low to high conductivity materials including solids, liquids, pastes, powders, soils, .

The fabrication of the sensor shown in Fig. 3 is as follows. (a–b) A ROL-7133 photoresist was spin-coated on the surface of the silicon wafer. . Additionally, thermal conductivity testing of . Fabrication of High Thermal Conductivity NARloy-Z-Diamond Composite Combustion Chamber Liner for Advanced Rocket Engines Biliyar N. Bhat Materials and Processes Laboratory . •Hot fire test to demonstrate performance improvements (TRL 5) 4. Thermal conductivity of Cu-Ag-Zr-D composites 5. The thermal conductivity, resistivity, and Seebeck coefficients were referred from the literature [27,28], and the coefficient values are represented in Table 2. . 2.2 Fabrication and performance measurement .Thermal conductivity testing has diverse applications. It is crucial in fields such as construction, aerospace, electronics, and energy systems. It helps in selecting insulation materials, designing heat sinks, optimizing building envelope performance, and evaluating the thermal efficiency of various components and systems. .

from cavity thermal stability point of view, it is important to perform their measurement and specially for new materials (i.e coatings). 2 THERMAL CONDUCTIVITY A new apparatus was developed for measuring the thermal conductivity k(T) of materials commonly used for the fabrication of bulk niobium SRF cavities. ThisWe ensure regulatory compliance by conducting rigorous thermal conductivity testing according to internationally recognized standards such as ASTM C518 and ISO 8301. Our commitment to utilizing the latest state-of-the-art testing instrumentation enables us to accurately measure thermal conductivity and assess changes in thermal properties over . The thermal conductivity of the TIMs was measured by steady-state thermal methods (ASTM D5470 standard) using a thermal conductivity tester . Du, X. et al. Fabrication of liquid metal/diamond hybrid thermal interface materials with high thermal conductivity and low flowability. J Mater Sci: Mater Electron 34, 1395 (2023) . https://doi .

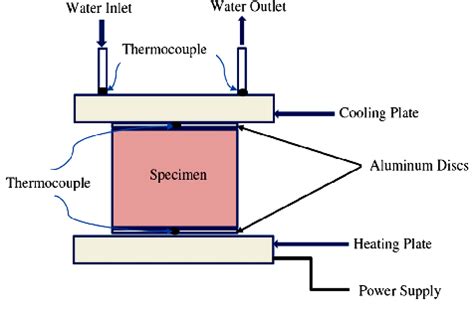

Fabrication and thermal conductivity improvement of novel composite adsorbents adding with nanoparticles Download PDF. Download PDF. Published: 24 October 2016 . 3. Testing of “BaCl2/vermiculite” composite in a lab-scale adsorption chiller[J]. Applied Thermal Engineering, 2010, 30: 1188–1192. Article Google Scholar The thermal conductivity tester DTC-300 (TA Instruments, New Castle, USA) is steady-state and uses a heat flux transducer to measure the heat flow through the specimen – see Fig. 1 a. A total of one sample with a diameter of ∅50 mm and a maximal thickness of 25.4 mm can be mounted between an upper “hot” and a lower “cold” plate .1, 2) for fabricating test coupons. NARloy-Z-D composites containing 10, 20 and 40vol% of high thermal conductivity diamond powder were investigated. Thermal conductivity (TC) data are shown in Figure 1. TC increased with increasing diamond content and showed 50% improvement over pure copper at 40vol% diamond (>500 W/mK). This TC was chosen as .The transient hot wire method (THW) is a very popular, accurate and precise technique to measure the thermal conductivity of gases, liquids, [3] solids, [4] nanofluids [5] and refrigerants [6] in a wide temperature and pressure range. The technique is based on recording the transient temperature rise of a thin vertical metal wire with infinite length when a step voltage is applied .

The thermal conductivity of the composites was measured through a DRL-III thermal conductivity tester (heat flux). Pellets of samples with a diameter of ∼28 mm were used for the measurements. To ensure accuracy, the average value calculated from three measurements was reported in this study. However, all solids—including metals—conduct heat via vibration between adjacent atoms. Certain solids like Styrofoam have a low k value and act as insulators. This is partially due to the low k value for air that is contained within the void spaces of these materials [4]. For more information on the theory behind thermal conductivity, see the video below:

Fabrication of High Thermal Conductivity NARloy-Z-Diamond Composite Combustion Chamber Liner for Advanced Rocket Engines . A subscale combustion chamber liner was designed to fit in an existing hot fire test assembly at Marshall Space Flight Center (MSFC) shown in Figure 2. It is basically a 2.75 in OD, 2.50 in ID and . The Thermal Protection Materials Branch consists of thermal protection material processing labs which are responsible for: Processing thermal protection materials such as PICA and CPICA (Conformal Phenolic Impregnated Carbon Ablator) in order to infuse the resin system into a carbon substrate and cure in an oven for further evaluation such as ground testing in .Thermal properties of carbon/carbon Fiber axial thermal conductivity (W/m-R) Composite Type II ribbon AR-120 4297 1501 composites formed from mesophase pitch-based towpreg and Type II ribbon fibers Final heat treatment temperature (“C) 1100 x-Direction thermal conductivity (W/mR) y-Direction thermal conductivity z-Direction thermal . Thermal conductivity enhancement of three times the base paraffin was reported utilizing the nickel-based conductivity enhancement while copper integration achieved about 5 . The fabrication and testing of the devices is reviewed in this section. Devices were constructed to examine the tendencies and effectiveness of low cost mechanical .

The state-of-the-art progress of flexible thermally conductive films with ultrahigh in-plane isotropic thermal conductivity (k) and potential application are summarized.The heat transfer mechanism, processing methods to enhance k, optimization strategies to reduce interface thermal resistance of flexible thermally conductive films are reviewed.. The limitations and . In this work, a novel micro-thermal conductivity detector (microTCD) with high sensitivity has been introduced, in which the two Pt-resistors on the same arm (reference arm or test arm) are . Since the thermal conductivity of crystalline alumina is 30 W/m K, while that of amorphous alumina is 0.2 W/m K-10 W/m K, and that of air is only 0.02 W/m K, 25 to improve the anodic coating's .

manual compression test quizlet

Therefore, thermal conductivity κ TIM and contact thermal resistance under the packaging pressure can be calculated from the linear fit of thickness dependent thermal conductivity. Fig. 3 (c) gives the linear relationship of R total = 2.16 t - 1.3 × 10 −2 cm 2 K/W under the (350 Kpa), where t represents the thickness of the thermal pad.

thermal conductivity tests

The thermal conductivity of the SiCN(O) ceramic aerogel composites was acquired on a thermocline-method (i.e., hot-wire method) thermal conductivity analyzers (XIATECH TC3200, Xian, China), the hot-wire method is a transient technique that measures temperature rise at a known distance from a linear heat source embedded in the test sample, .

We present the design, fabrication, and testing results of a single chip (2 cm×4 cm) micro gas separation column (μGC) with an embedded non-cascaded micro thermal conductivity detector (μTCD). DOI: 10.1016/S0924-4247(02)00144-9 Corpus ID: 111128669; Fabrication and characterization of thermal conductivity detectors (TCDs) of different flow channel and heater designs This is mainly due to its high electrical and thermal conductivity, chemical stability, relatively low cost (compared to gold or graphene, for example), and the ability of its oxide form to .

manual compression test stand

The thermal conductivities of the melilite-spinel porous ceramics after sintering at 1150 °C are shown in Table 1. The porous ceramics exhibited an ultralow thermal conductivity at all testing temperatures, with values of 0.036 W/(m The samples show a surface thermal conductivity value of approximately 533 W-1

thermal conductivity testing near me

31 de dez. de 2020 · There was a video where a man whose face was peeled begging for water while being interrogated. Can anyone translate the conversation between the .

Thermal Conductivity Tester fabrication|thermal conductivity testing methods